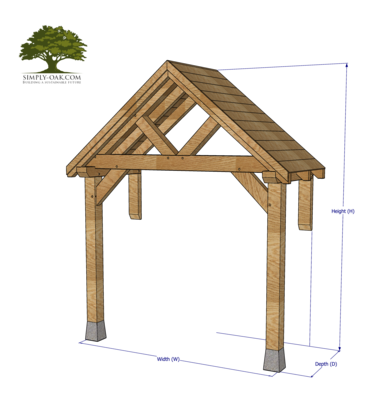

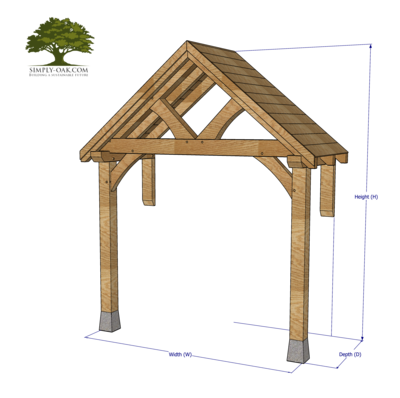

Half Post - The Angular - Std Sizes

Half Post - The Angular - Std Sizes

For each individual frame, we order the required British QPA 1 grade green oak to ensure the best quality and moisture content, that allows us to handwork the timber.

We buy oversized oak and carefully plane each face a minimum of four times. Before each run, the oak is inspected for the quality of the grain and to ensure there are no defects. Once the oak is planed we then sand each face until the final dimensions are achieved.

Using traditional framing techniques choosing the working face, our team use a mixture of hand-tooling to mark out and fabricate the mortise and tenon joints. The roofing makeup including the oak rafters and truss is measured, marked out, fabricated and fitted.

Once the frame is complete we check all joints for tolerance and adjust if required. The frame is then dismantled, each component is sanded to remove all workings and to bring out the final grain.

To ensure all our frames are completed to the highest standard we only install our frames. We use traditional offset pegging to tie the frame together and use the minimum number of mechanical fixings needed.

As our frames are sanded after fabrication they need no aftercare or treatment. The oak will naturally age initially in an orange phase when the tannins are released and after that, the oak will gradually silver.

During the ageing process, the oak will also crack which is known as 'shakes'. This process is entirely natural and does not affect the structural integrity of the frame. Once the frame is installed, we provide a 10-year structural guarantee.

[tab name='Std']

| Width / Roof Width | 1700 mm / 2020 mm |

| Depth / Roof Depth | 1120 mm / 1225mm |

| Height | 3090 mm |

| Roof Pitch | 45 ° |

| Lead Time | 4 weeks |

[tab name='Grand']

| Width / Roof Width | 2575 mm / 2815 mm |

| Depth / Roof Depth | 1120 mm / 1225 mm |

| Height | 3325 mm |

| Roof Pitch | 40 ° |

| Lead Time | 4 weeks |

[tab name="Bespoke Size" ]

| Click for bespoke options |